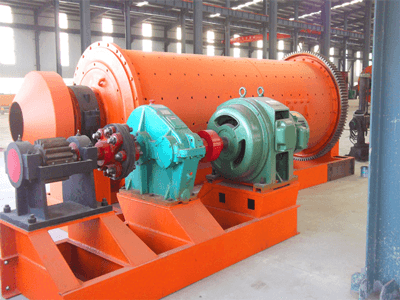

[Introduction] Ball mill with discharging grid.

[Cylinder Diameter] 900mm-4500mm

[Application] Often used to grind ore with coarse grain size.

[Improvement] The cylinder of wet grid ball mill can use high wear-resistant rubber liner, which has good wear resistance, long service life and convenient maintenance.

Chat With Us

Chat With Us

Leave Message

Leave Message

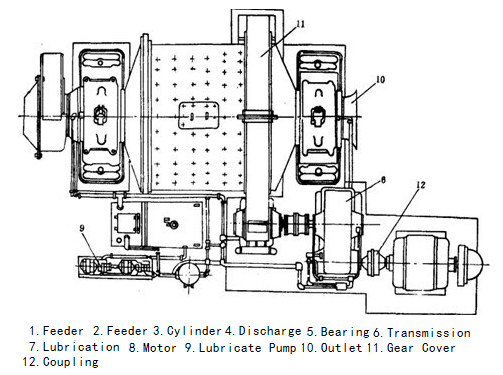

Advantages

1. Equipped with a lifting device for easy maintenance.

2. Static and dynamic bearing, stable and reliable operation.

3. Slow-speed transmission, easy to repair and start.

4. Oil mist lubrication device to ensure reliable lubrication of large and small gears.

5. Flexible start of the gas clutch.

Structure

This machine is a horizontal cylindrical rotating device, driven by external gears, two chambers, grid ball mill. Ores enter the first chamber of the mill evenly by screw through the hollow shaft of the feeding device. There are corrugated lining plates and steel balls in the first chamber. The centrifugal force produced by the rotation of the cylinder brings the steel ball to a certain height and then falls down, which has a heavy blow and grinding effect on the ores. After the material is roughly grinded in the first chamber, it enters the second chamber through a single-layer partition board. The second chamber is equipped with flat lining plates and steel balls to further grind the ores. The powder is discharged through the discharging grate.

Technical Parameter

|

Model |

Cylinder |

Motor Model |

Power kw |

Installation Size mm |

Volume |

Ball Loading |

Weight |

||||

| Diameter mm |

Length mm |

Revolution rpm |

Length | Width | Height | ||||||

| MQG0909 | 900 | 900 | 39.2 | Y225S-8 | 18.5 | 4027 | 2213 | 2015 | 0.45 | 0.96 | 4400 |

| MQG0918 | 900 | 1800 | 39.2 | Y225M-8 | 22 | 4196 | 2336 | 2015 | 0.9 | 1.92 | 5340 |

| MQG1212 | 1200 | 1200 | 31.3 | Y250M-8 | 30 | 4500 | 2104 | 1733 | 1.1 | 2.4 | 11438 |

| MQG1224 | 1200 | 2400 | 31.3 | Y280M-8 | 45 | 5764 | 2104 | 1733 | 2.4 | 4.6 | 13200 |

| MQG1515 | 1500 | 1500 | 30.9 | JR115-8 | 60 | 6094 | 2743 | 2170 | 2.5 | 5 | 13120 |

| MQG1530 | 1500 | 3000 | 30.9 | JR117-8 | 80 | 6800 | 2743 | 2170 | 5.08 | 8.6 | 19166 |

| MQG1545 | 1500 | 4500 | 30.9 | JR127-8 | 130 | 9085 | 3091 | 2170 | 6.57 | 11.3 | 22147 |

| MQG2122 | 2100 | 2200 | 24.05 | JR128-8 | 155 | 7750 | 4450 | 3533 | 6.6 | 16 | 42500 |

| MQG2130 | 2100 | 3000 | 24.05 | JR137-8 | 210 | 8330 | 4450 | 3533 | 9 | 20 | 44260 |

| MQG2145 | 2100 | 4500 | 24.05 | JR138-8 | 245 | 9933 | 4450 | 3533 | 13 | 23.5 | 50348 |

| MQG2430 | 2400 | 3000 | 22.5 | JR138-8A | 280 | 8823 | 5113 | 3894 | 12.1 | 22.5 | 58328 |

| MQG2436 | 2400 | 3600 | 22.5 | JR138-8B | 320 | 9455 | 5113 | 3894 | 14.5 | 26 | 61308 |

| MQG2727 | 2700 | 2700 | 21.6 | JR138-8B | 320 | 8643 | 5722 | 4674 | 15.3 | 30 | 83145 |

| MQG2736 | 2700 | 3600 | 21.6 | JR1510-8 | 400 | 10463 | 5942 | 4674 | 18.4 | 36 | 89120 |

| MQG2745 | 2700 | 4500 | 21.6 | TDMK500-32 | 500 | 11471 | 5907 | 4674 | 23 | 45 | 109318 |

| MQG3236 | 3200 | 3600 | 18.5 | TDMK630-36 | 630 | 12442 | 7030 | 5150 | 25.6 | 51 | 144241 |

| MQG3245 | 3200 | 4500 | 18.5 | TDMK800-36 | 800 | 13975 | 7030 | 5150 | 32.8 | 65 | 153390 |

| MQG3639 | 3600 | 3900 | 17.3 | TDMK1000-40 | 1000 | 15000 | 7200 | 6300 | 36.2 | 75 | 168800 |

| MQG3645 | 3600 | 4500 | 17.3 | TDMK1250-40 | 1250 | 15200 | 7750 | 6300 | 41.8 | 90 | 179900 |

| MQG3650 | 3600 | 5000 | 17.3 | TDMK1400-40 | 1400 | 17600 | 7750 | 6300 | 46.4 | 96 | 183000 |

| MQG3660 | 3600 | 6000 | 17.3 | TDMK1600-40 | 1600 | 17000 | 8800 | 6500 | 55.7 | 120 | 204000 |

| MQG4060 | 4000 | 6000 | 16.2 | TDMK1700-30 | 1700 | 17400 | 9500 | 7600 | 69.8 | 137 | 214000 |

| MQG4560 | 4500 | 6000 | 15..3 | TDMK2300-30 | 2300 | 17800 | 10500 | 7600 | 87 | 158 | 294000 |