[Introduction] New technology is adopted in high-efficiency thickener for flocculant addition, ore feeding, automatic control and internal structure. Compared with commen thickener, high efficiency improved thickener has the advantages of large production capacity, small transmission power, compact structure and small area.

[Capability] 5-1400t/d

[Application] It is suitable for mines with large capacity and low product concentration, mainly used for concentrate concentration and tailings dewatering in concentrators, and also widely used for concentration and purification of solid granular liquids in chemical industry, building materials, water source and sewage treatment industry.

[Improvement] After improvement, the treatment capacity is high, the overflow turbidity is low, and the discharge concentration is high.

Chat With Us

Chat With Us

Leave Message

Leave Message

Advantages

Structure

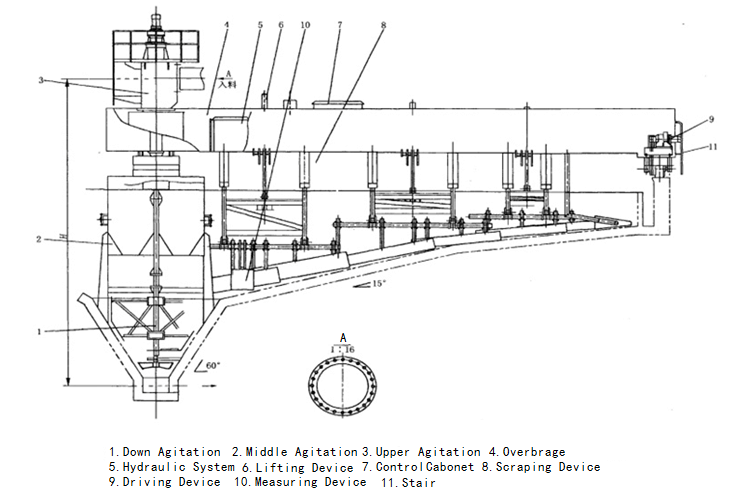

The highly efficient improved thickener mainly consists of a circular concentrator and a rake mud scraper. The solid particles suspended in the slurry settle under the action of gravity in the concentrator, and the upper slurry becomes clarified water, which separates the solid from the liquid. The sludge deposited at the bottom of the concentrator is continuously scraped and collected by the rake mud scraper and discharged from the central outlet of the bottom of the pond, while the clarified water overflows from the upper part of the thickener.

Technical Parameter

|

Model |

Diameter mm |

Depth mm |

Area m2 |

Capacity tpd |

Motor |

Power kw |

Weight kw |

|

NJG-2.5 |

2500 |

1850 |

4.9 |

5-22.4 |

Y90L-6 |

1.1 |

2225 |

|

NJG -3A |

3000 |

1800 |

7 |

5-23.3 |

Y100L-6 |

1.5 |

3168 |

|

NJG -3 |

3600 |

1800 |

10.2 |

5-28.5 |

Y100L-6 |

1.5 |

3680 |

|

NJG -5 |

5000 |

2956 |

16 |

16-90 |

Y90L-4 |

1.5 |

7908 |

|

NJG -6 |

6000 |

2956 |

28.3 |

98 |

Y90L-4 |

1.5 |

8772 |

|

NJG -7 |

7000 |

3000 |

38.5 |

140 |

Y112M-6 |

2.2 |

13862 |

|

NJG -8 |

8000 |

3318 |

50.2 |

185 |

Y132S-6 |

3 |

19158 |

|

NJG -9 |

9000 |

3376 |

63 |

210 |

Y132S-6 |

3 |

21733 |

|

NJG -12 |

12000 |

3600 |

113 |

370 |

Y132S-6 |

3 |

34823 |

|

NJG -15 |

15000 |

3600 |

176 |

580 |

Y132S-4 |

5.5 |

54315 |

|

NJG -18 |

18000 |

4400 |

255 |

960 |

YCT200-4B |

7.5 |

73588 |

|

NJG -20 |

20000 |

4400 |

315 |

1400 |

YCT200-4B |

7.5 |

76312 |