[Introduction] Cyclone set with high classification efficiency.

[Capability] less than 2500m3/h.

[Application] Hydraulic cyclone set is used to separate heavy coarse granular mud and sand, classify, concentrate, dehydrate, desliming, desanding, washing, superfine classification, etc.

[Improvement] Gate-free valves are installed at the feeding ports of each mine. The valves are reliable in operation and have small resistance to movement. Meanwhile, the size of the valves is very small, which reduces the diameter of the whole cyclone group.

Chat With Us

Chat With Us

Leave Message

Leave Message

Advantages

Structure

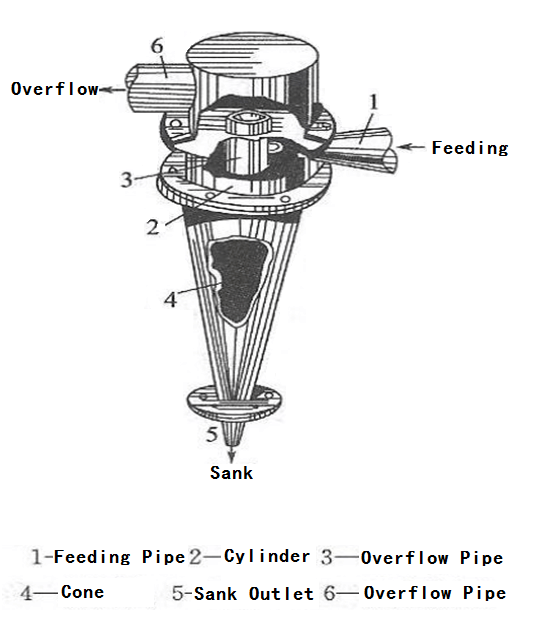

When the mixed liquid to be separated enters the hydrocyclone at a certain pressure from the feed port of the hydrocyclone, a strong three-dimensional elliptical strong rotational shear turbulence is generated. Due to the different density of particles, the centrifugal force, centripetal buoyancy, fluid drag force and other sizes are different. Under centrifugal sedimentation, most of the coarse particles (or heavy phases) are discharged through the underflow port of the cyclone, while most of the fine particles (or light phases) are discharged by the overflow pipe, thus achieving the purpose of separation and classification.

Technical Parameter

|

Model |

Specification |

Capacity m3/h |

Particle Size μm |

Overflow Outlet Diameter mm |

Sank Outlet Diameter mm |

|

XC II F 150 |

150 |

10 ~23 |

25 ~74 |

30 ~50 |

8~22 |

|

XC II F 200 |

200 |

17 ~38 |

28 ~80 |

40 ~65 |

16 ~32 |

|

XC II F 250 |

250 |

24 ~53 |

30 ~82 |

65~100 |

16 ~40 |

|

XC II F 300 |

300 |

40~100 |

36 ~90 |

65~120 |

20 ~40 |

|

XC II F 350 |

350 |

56~118 |

40~100 |

80~120 |

30 ~70 |

|

XC II F 375 |

375 |

74~157 |

42~105 |

90~135 |

30 ~70 |

|

XC II F 450 |

450 |

90~192 |

44~110 |

100~150 |

30 ~70 |

|

XC II F 500 |

500 |

128~300 |

50~115 |

130~220 |

35~100 |

|

XC II F 550 |

550 |

155~368 |

52~120 |

140~240 |

35~100 |

|

XC II F 600 |

600 |

200~468 |

57~125 |

160~260 |

65~110 |

|

XC II F 660 |

660 |

237~524 |

60~130 |

180~280 |

80~150 |