Chat With Us

Chat With Us

Leave Message

Leave Message

1. Processing of high whiteness fine powder and ultrafine powder. High whiteness fine grinding barite powder is made from barite raw ore by grinding, washing and whitening.

2. Production of barium salt products, such as lithopone (zinc barium white), barium chloride, barium hydroxide, etc.

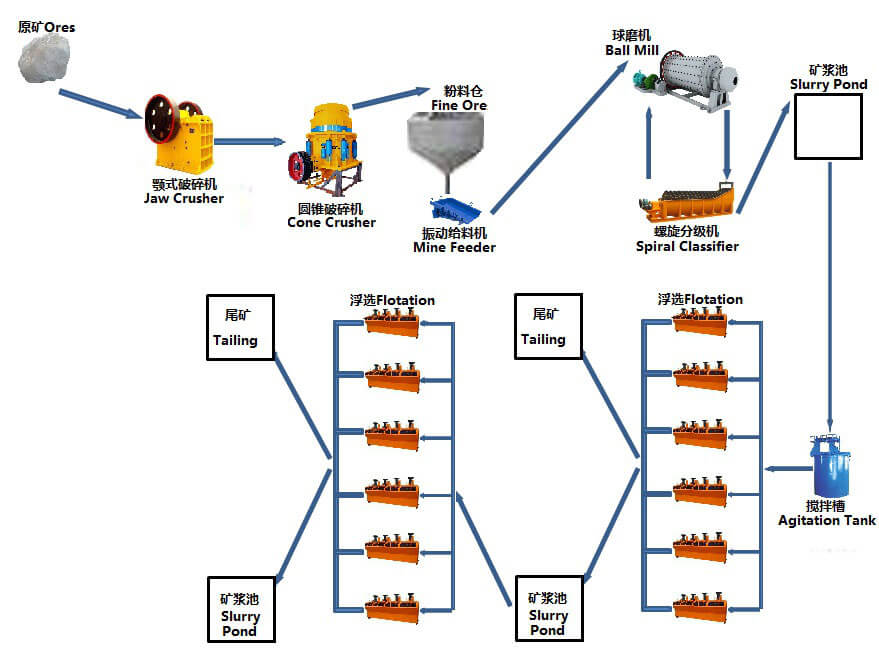

The usual method is to crush and screen. Through jigging beneficiation process, concentrate with high grade can be obtained, and the concentrate grade can be more than 80%. For crushing process, adopt jaw crusher and two-stage crushing process to crush the exploited barite. The screening process adopts circular vibrating screen with large processing capacity.

Wet magnetic separators are usually used to separate some iron-bearing materials, such as siderite, for barite raw materials requiring barium-based drugs with very low iron content.

Flotation is often used for the separation of barite ore with very fine particle size and its gravity tailings. According to different adsorption modes, barite was flotation by using anionic collectors such as aliphatic acid alkyl sulfate, alkyl sulfonate or cationic amine collectors.