Chat With Us

Chat With Us

Leave Message

Leave Message

1. Large scale gold process plant with high gold grade.

2. Gold concentrate after flotation.

3. Amalgamation of mercury or reprocessing of tailings with high gold content.

4. Oxidized gold-bearing ore with more mud.

The process of gold carbon slurry is a non-filtration gold extraction process using activated carbon to directly adsorb and recover gold from cyanide slurry. The whole process includes preparation of leaching slurry, cyanide leaching, adsorption of activated carbon, desorption of gold-bearing carbon, electrolysis into gold mud, degold carbon recycling, and treatment of leaching slurry.

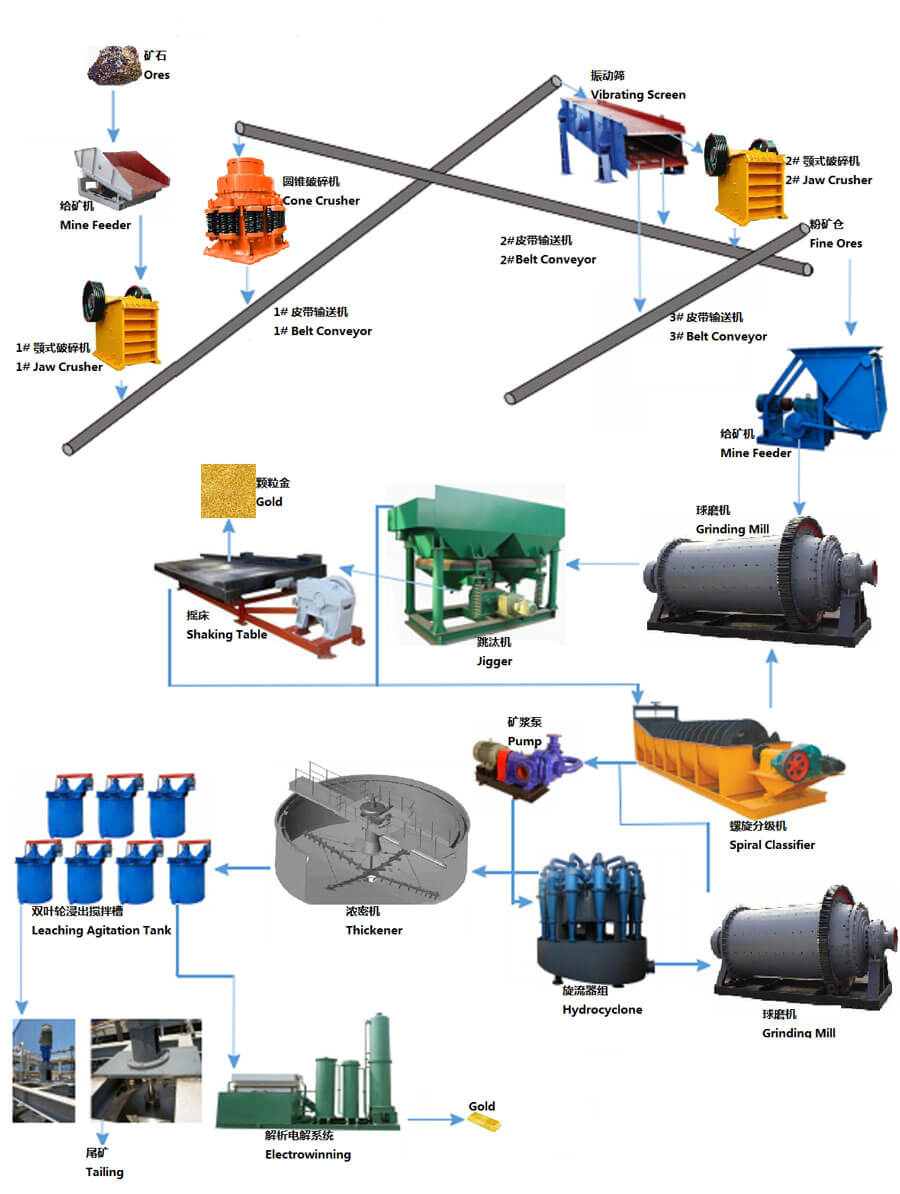

Raw Material Preparation

Grind the gold ore to be size suitable for cyanidation, generally required to be less than 28 mesh, and remove wood chips and other impurities from slurry, the concentration of leached pulp reaches 45% ~ 50% after concentration dehydration.

Agitation Leaching

This stage is the same as the conventional cyanidation method, which needs 5~8 leaching tanks.

Activated Carbon Adsorption

The activated carbon is added into the leaching tank, and the activated carbon can absorb the gold in the pulp and become the gold-bearing carbon. After the adsorption is completed, the activated carbon and the pulp are separated by the carbon sieve. Generally, there is a screen and a pulp elevator in the carbon slurry tank, which can realize the reverse flow of activated carbon and pulp, adsorb the dissolved gold in the pulp, and reduce the wear of activated carbon. However, the bridge screen is easy to be activated carbon plug, to use compressed air cleaning.

Gold-bearing Carbon Desorption

Common desorption methods include desorption of hot caustic sodium cyanide solution, desorption of low concentration caustic sodium cyanide solution with alcohol, desorption of high concentration caustic sodium cyanide solution with high temperature and pressure.

Electrodeposition or conventional zinc powder replacement of precipitated gold

The gold-bearing carbon desorption can generally obtain the high-grade expensive liquid containing up to 600 g/m3 of gold, the gold powder can be obtained by electrodeposition or zinc replacement, and the gold ingots can be obtained by smelting.

The regeneration of activated carbon

The activated carbon after desorption is first pickling with dilute sulfuric acid (nitric acid) to remove the accumulation of carbonate, etc. After several times of return to use, thermal activation is required to restore the adsorption activity of carbon.

Gold extraction by carbon slurry method is mainly applicable to gold-bearing oxidized ore with high slime content. Due to high slime content of ore and difficulty in solid-liquid separation, the existing filter cannot effectively separate expensive liquid and slag, so conventional cyanidation method cannot obtain better technical and economic indicators. Before adsorption, cyanide slurry should be treated with wood chips and other impurities to avoid the gold and activated carbon in the wood chips adsorption slurry mixed with rich carbon and prevent wood chips from blocking the carbon screen.

The main equipment

Cyanidation — the main equipment used in the gold extraction process of zinc powder replacement includes thickener, leaching tank, deoxidation tower, zinc powder adding device, filter press, dosing machine, gold mud smelting equipment, etc.