Chat With Us

Chat With Us

Leave Message

Leave Message

1. Mines with high predominant silver content.

2. Silver content is lower than the industrial index, and silver is associated with other metallic minerals.

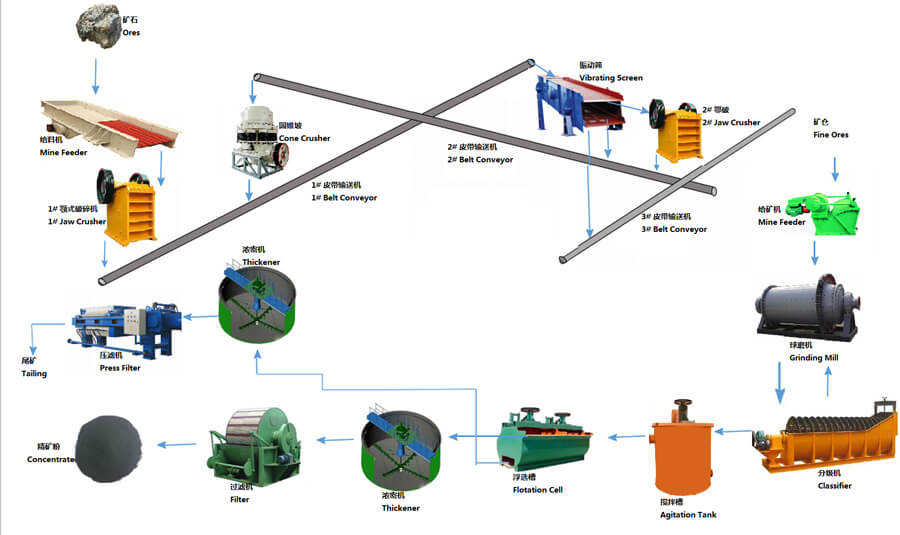

The main factors affecting flotation efficiency include grinding fineness, dosage of reagent, pulp concentration, aeration and flotation time, etc. Flotation process needs to be determined according to beneficiation test. The process flow is one of the main factors affecting mineral flotation. The design of the process flow should take into account the properties of ore, the ease of operation of the concentrator, the operation cost and the recovery of various useful minerals.

For silver ores with silver as the main ore, uniform particle size distribution and relatively coarse particle size, a one-stage grinding-floatation process is usually adopted. For ores with uneven distribution of silver in coarse and fine grains, mercury plates or gravity separation equipment are usually placed between the grinding and classification to recover silver grains in advance. For silver ores with other precious metals, flotation process is also more complex