[Introduction] One type grinding equipment with steel rod as grinding medium.

[Productivity] 0.62-250t/h

[Application] Rod mill is mainly used for rough grinding operation. It is suitable for fine grinding and rough grinding of ores in the first stage of grinding, especially for handling brittle materials.

[Improvement] Wet rod mill has three types: overflow rod mill, end peripheral rod mill and center peripheral rod mill, which can meet the different needs of customers.

Chat With Us

Chat With Us

Leave Message

Leave Message

Advantages

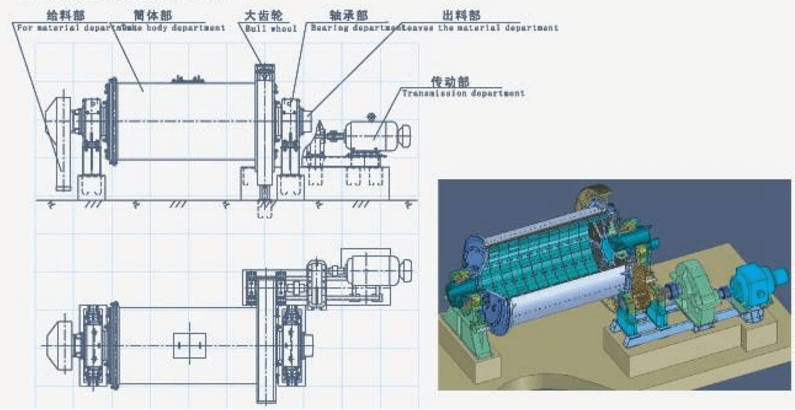

Structure

The motor connects the reducer through the pinion, drives the big gear to rotate, then drives the rotation part to rotate, and the cylinder body is filled with appropriate grinding medium-steel rods. Under the action of centrifugal force, the steel rods rotate along with the cylinder, when the steel rods reaches a certain height, they will fall and crush the ores, the crushed ores and water become mixed pulp, then under the force of cylinder rotating, the pulp will be discharged out of the cylinder.

Technical Parameter

|

Model |

Cylinder |

Motor |

Installation Dimension(mm) |

Volume m3 |

||||||

|

Diameter mm |

Length mm |

Revolution rpm |

Model |

Power kw |

Length |

Width |

Height |

|||

|

MBY0918 |

900 |

1800 |

22 |

Y225M-8 |

730 |

4980 |

2370 |

2020 |

0.62~3.2 |

|

|

MBY0924 |

900 |

2400 |

30 |

Y250M-8 |

730 |

5670 |

3280 |

2020 |

0.81~4.3 |

|

|

MBY1224 |

1200 |

2400 |

45 |

Y280M-8 |

730 |

6450 |

2800 |

2500 |

0.4~4.9 |

|

|

MBY1530 |

1500 |

3000 |

95 |

JR125-8 |

725 |

7935 |

3185 |

2280 |

0.4~4.9 |

|

|

MBYg1530 |

1500 |

3000 |

80 |

JR117-8 |

725 |

7253 |

3070 |

2280 |

2.4~7.5 |

|

|

MBYg2130 |

2100 |

3000 |

180 |

JR136-8 |

735 |

8122 |

4220 |

3073 |

14~35 |

|

|

MBYg2136 |

2100 |

3600 |

210 |

JR137-8 |

735 |

8958 |

4320 |

3025 |

43~61 |

|

|

MBYg2430 |

2400 |

3000 |

280 |

JR138-8 |

735 |

9005 |

4836 |

3490 |

43~61 |

|

|

MBYg2732 |

2700 |

3200 |

320 |

JR157-8 |

750 |

10509 |

5000 |

3620 |

43~61 |

|

|

MBYg2736 |

2700 |

3600 |

380 |

JR158-8 |

743 |

10764 |

5750 |

3620 |

32~86 |

|

|

MBY2740 |

2700 |

4000 |

400 |

TDMK400-32 |

187.5 |

12300 |

5700 |

4700 |

43~110 |

|

|

MBY3040 |

3000 |

4000 |

570 |

JR1510-8 |

740 |

9800 |

3900 |

3900 |

54~135 |

|

|

MBY3245 |

3200 |

4500 |

800 |

TDMK800-36 |

167 |

14600 |

7000 |

5300 |

64~180 |

|

|

MBY3645 |

3600 |

4500 |

1250 |

TDMK1250-40 |

150 |

15200 |

8800 |

6800 |

80~230 |

|

|

MBY3654 |

3600 |

5400 |

1600 |

TDMK1600-40 |

150 |

15900 |

8800 |

6800 |

100~250 |

|