[Introduction] Cone crusher is an advanced crusher with high power, high crushing ratio and high productivity. Spring is not only a safety device, but also affects the crushing force.

[Productivity] 12-700 t/h

[Application] Cone crusher is suitable for crushing raw materials in metallurgy, construction, road construction, chemistry and silicate industries. It can crush all kinds of ores and rocks with medium size and medium hardness.

[Improvement] Mine crusher incorporates accumulator into a fixed cone hydraulic locking system, which runs more smoothly. The moving cone is suspended by a spherical bearing, and the seal is durable with a water-sealed dust-proof device.

Chat With Us

Chat With Us

Leave Message

Leave Message

Advantages

Structure

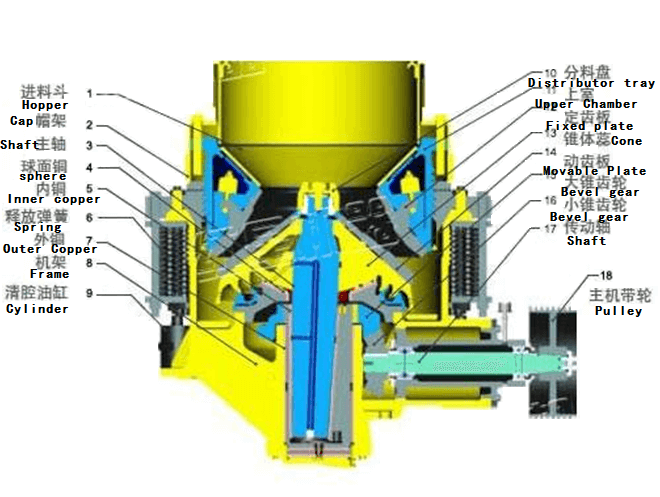

Crusher is mainly composed of frame, fixed cone assembly, moving cone assembly, spring mechanism, bowl-shaped shafting, and transmission, and its auxiliary part is composed of electrical system, oil lubrication system and hydraulic cavity cleaning system.

When working, the motor drives the eccentric sleeve to rotate through the belt, the big pulley, the transmission shaft, the small bevel gear, and the big bevel gear. The broken taper axis swings under the force of the eccentric sleeve, which makes the crushing plate close to and away from the rolling mortar plate, so that the material is continuously impacted, extruded and bent in the annular crushing chamber composed of the fixed cone and the moving cone. Bend and break. After repeated extrusion, impact and bending, the material is crushed to the required size and discharged through the lower part of the crusher.

Technical Parameter

| Model | Crushing Cone Diameter mm | Feeding Size mm | Outlet mm | Capacity t/h | Motor Power kw | Weight t |

| PYB600 | 600 | 65 | 12-25 | 40 | 30 | 5 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | ||

| PYB900 | 900 | 115 | 15-50 | 50-90 | 55 | 11.2 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | ||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | ||

| PYB1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 24.7 |

| PYZ 1200 | 100 | 20-50 | 42-135 | 25 | ||

| PYD1200 | 50 | 8-25 | 18-105 | 25.3 | ||

| PYB 1750 | 1750 | 215 | 25-50 | 180-360 | 160 | 50.3 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | ||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | ||

| PYB2200 | 2200 | 300 | 30-60 | 420-700 | 280-260 | 80 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | ||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 |