[Introduction] A complete set of system is applied to the treatment of gold-bearing charcoal in the coal pulp plant of gold mines, so that gold can be separated from the gold-bearing charcoal and precipitated into high-grade gold sludge.

[Gold Carbon Content] Over 3.5kg/t

[Application] It is used to extract solid gold from gold-bearing carbon by cyanidation.

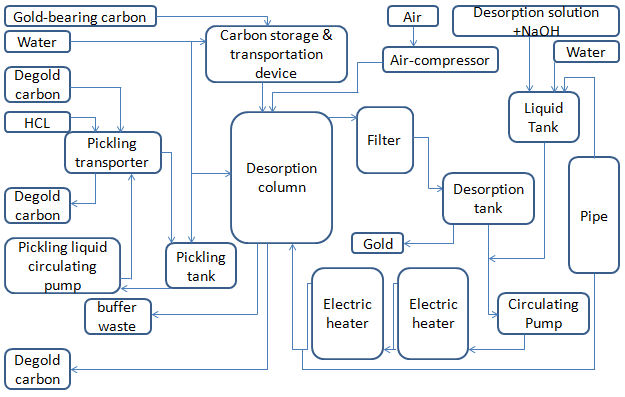

[Improvement] The desorption electrolysis system consists of desorption column, electrolyzer, electric heater, desorption liquid tank, filter, electronic control cabinet, rectifier cabinet, circulating pump, activated carbon regeneration kiln, etc.

Chat With Us

Chat With Us

Leave Message

Leave Message

Advantages

Structure

The desorption electrolysis system adds anions easily adsorbed by activated carbon to the desorption system, thus replacing Au(CN)2-to realize gold desorption. The precious liquid obtained by desorption of gold-loaded carbon is recovered by ionization method to obtain solid gold.

The desorption electrolysis device is mainly composed of desorption and electrolysis. The process of desorption and electrolysis is separated so that the solvent is carried out in a comprehensive desorption tower. The noble liquid electrolysis is completed in an independent electrolytic cell. The four processes of solvent desorption, noble liquid heating, solvent condensation and solvent recovery are centralized in a comprehensive desorption tower, and the noble liquid obtained by solvent vapor desorption of gold-loaded carbon is concentrated. The crude gold is obtained by electrolysis in a separate electrolytic cell through a pipeline, and then the finished gold is purified.

Technical Parameter

|

Desorption electrolysis system |

|||

|

Model |

Capacity (t/d) |

Ore Grade (g/t) |

Parameter |

|

GJD-200 |

<150 |

2–8 |

Working Temperature:150℃ |

|

GJD-300 |

150-300 |

2–8 |

|

|

GJD-500 |

300-500 |

2–8 |

|

|

GJD-700 |

|||

|

GJD-1000 |

500-1000 |

2–8 |

|

|

GJD-1500 |

|||

|

GJD-2000 |

1000-2000 |

2–20 |

|

|

GJD-2500 |

|||

|

GJD-3000 |

|||

|

GJD-3500 |

2000-3000 |

2–20 |

|

|

GJD-4000 |

|||

|

GJD-5000 |

|||

|

GJD-8000 |

3000-5000 |

2–20 |

|

|

Electric Heating Technology |

||||||

|

Model |

Working Temperature ℃ |

Working Medium |

Heat Power kw |

Voltage V |

Weight kg |

Remarks |

|

JDDR6 |

40 |

NH4SCN |

2×3 |

380 |

80 |

Resin desorption |

|

JDDR18 |

98 |

1%NaOH+2%NaOH |

6×3 |

380 |

|

|

|

JDDR24 |

98 |

1%NaOH+2%NaOH |

8×3 |

380 |

147 |

|

|

JDDR36 |

98 |

1%NaOH+2%NaOH |

6×6 |

380 |

|

|

|

JDDR48 |

98 |

1%NaOH+2%NaOH |

8×6 |

380 |

138 |

|

|

Electric Heating Technology |

||||||

|

Model |

Working Temperature ℃ |

Working Medium |

Heat Power kw |

Voltage V |

Weight kg |

Remarks |

|

JDDR6 |

40 |

NH4SCN |

2×3 |

380 |

80 |

Resin desorption |

|

JDDR18 |

98 |

1%NaOH+2%NaOH |

6×3 |

380 |

|

|

|

JDDR24 |

98 |

1%NaOH+2%NaOH |

8×3 |

380 |

147 |

|

|

JDDR36 |

98 |

1%NaOH+2%NaOH |

6×6 |

380 |

|

|

|

JDDR48 |

98 |

1%NaOH+2%NaOH |

8×6 |

380 |

138 |

|