[Introduction] Mixing equipment for forcing pulp to circulate up and down in the tank.

[Effective Volume] 0.58-45m3

[Application] It is mainly used for slurry mixing before flotation operation to make the reagent and slurry fully mixed. It can also be used for slurry mixing in chemical industry, building materials industry, cyanide chemical plant, sewage treatment plant and other industries.

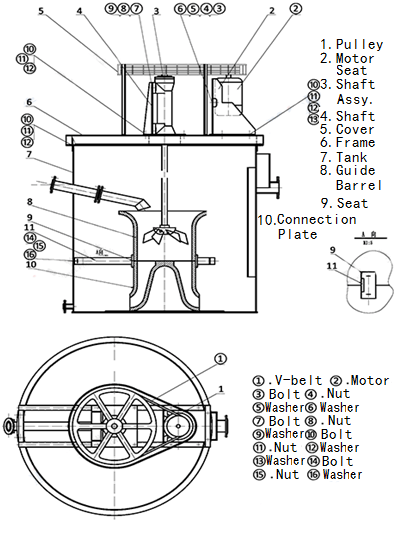

[Improvement] The unique umbrella impeller exerts downward pressure on the pulp, which makes the pulp circulate up and down along the draft tube. The mixture of the reagent and the pulp is more sufficient, the mixing ability is enhanced, and the circulation ability of the medicine and ore is stronger.

Chat With Us

Chat With Us

Leave Message

Leave Message

The high efficiency agitation tank is a kind of agitator which can make the pulp circulate up and down inside the agitator tank. The motor drives the impeller to rotate through the pulley, and then mixes the slurry and the reagent.

|

Model |

Volume m3 |

Impeller |

Motor |

Weight kg |

||

|

Revolution r/min |

Diameter mm |

Model |

Power kw |

|||

|

GBJ-1000×1000 |

0.58 |

530 |

240 |

Y112M-6 |

2.2 |

1548 |

|

GBJ-1250×1250 |

1.4 |

350 |

240 |

Y100L2-4 |

3 |

1808 |

|

GBJ-1500×1500 |

2.2 |

320 |

420 |

Y132M2-6 |

5.5 |

2207 |

|

GBJ-2000×2000 |

4.4 |

240 |

560 |

Y160L-6 |

11 |

3150 |

|

GBJ-2500×2500 |

11.2 |

271 |

560 |

Y180L-6 |

15 |

3943 |

|

GBJ-3000×3000 |

19.1 |

240 |

700 |

Y225S-8 |

18.5 |

4613 |

|

GBJ-4000×4000 |

37 |

180 |

900 |

Y280S-6 |

45 |

9249 |