[Introduction] Hydraulic crusher is fine crusher adopts hydraulic system to adjust the discharge port and overload protection.

[Productivity] 110-790t/h

[Application] It can be used for crushing materials in mining, construction, energy, chemistry, and other industries. It can crush all kinds of ores and rocks with medium size and medium hardness. Hydraulic cone crushing ratio and efficiency are high, energy consumption is low, product size is uniform, suitable for medium crushing and fine crushing.

[Improvement] Both ends of the spindle are supported, the shape of the crushing chamber is designed more scientifically, and the hydraulic and lubrication system is controlled by double insurance.

Chat With Us

Chat With Us

Leave Message

Leave Message

Advantages

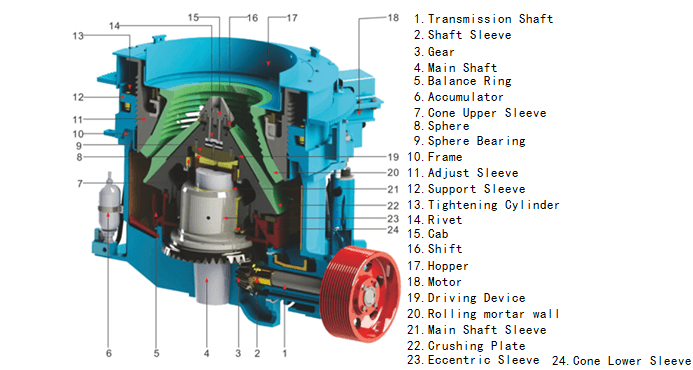

Structure

The motor drives the pinion of crusher, the pinion drives the big gear, the big gear drives the eccentric sleeve assembly and the spindle assembly centering on the theoretical vertical line, rotates in the copper bushing, and the spindle assembly can rotate in the eccentric copper sleeve with the centerline of the spindle.

When the airplane is running, the eccentric sleeve assembly drives the spindle assembly to rotate with the big gear. When the material is added to the crushing chamber, the spindle assembly rotates slowly in the eccentric copper sleeve under the resistance of the material. The trajectory of the inner cone seems to oscillate back and forth in the crushing chamber, while slowly rotating.

The material is crushed by the swinging inner cone. When metal blocks and other non-fragile objects fall into the crusher, the dynamic cone of the single-cylinder is supported by the bottom hydraulic piston, which plays the role of adjusting the discharge outlet, protecting the iron passage and eliminating the blockage by repeatedly rising and falling.

Technical Parameter

| Model | Chamber Type | Outlet mm | Inlet mm | Capacity t/h | Motor Power kw | Weight t |

| HPT200 | F | ≥13 | 95 | 120-200 | 160 | 13.5 |

| M | ≥16 | 120 | 140-220 | |||

| C | ≥19 | 190 | 150-250 | |||

| HPT300 | F | ≥13 | 105 | 110-260 | 250 | 18 |

| M | ≥16 | 150 | 175-320 | |||

| C | ≥20 | 210 | 190-380 | |||

| HPT400 | F | ≥14 | 110 | 185-345 | 315 | 26 |

| M | ≥20 | 196 | 255-430 | |||

| C | ≥25 | 251 | 295-560 | |||

| HPT500 | F | ≥16 | 135 | 280-455 | 400 | 37 |

| M | ≥22 | 210 | 345-605 | |||

| C | ≥30 | 290 | 405-790 |