[Introduction] Cyanide leaching stirring equipment.

[Volume] 6-1740m3

[Application] Double impeller leaching stirred tank is suitable for gold leaching, adsorption and other mixing operations with small specific gravity, low viscosity, slow settling speed, ore particle size more than 90% in 200 mesh and pulp concentration less than 45%.

[Improvement] Double impeller, uniform mixing, low energy consumption. The impeller is coated with glue and has a long service life. Multi-point air supply is adopted, and the air is evenly inflated.

Chat With Us

Chat With Us

Leave Message

Leave Message

Advantages

1.Smooth ore flow, uniform pulp mixing, and less energy consumption.

2. Air enters the groove through the transmission hollow shaft and is agitated by the blades so that the air is evenly dispersed.

3.Compact structure and convenient maintenance.

4. The hollow axis is ventilated to the bottom, through which the air enters the groove, and the air is evenly dispersed with small bubbles.

5. Using two new impellers, the impeller of the stirring tank has a large diameter, low rotating speed and low stirring power consumption, which can reduce carbon wear.

6. The moderate stirring intensity and consistent pulp concentration and fineness distribution in the tank can improve the cyanide leaching rate and carbon adsorption rate.

7. The impeller lining of the leaching stirring tank has wear-resistant rubber, low speed, and long service life.

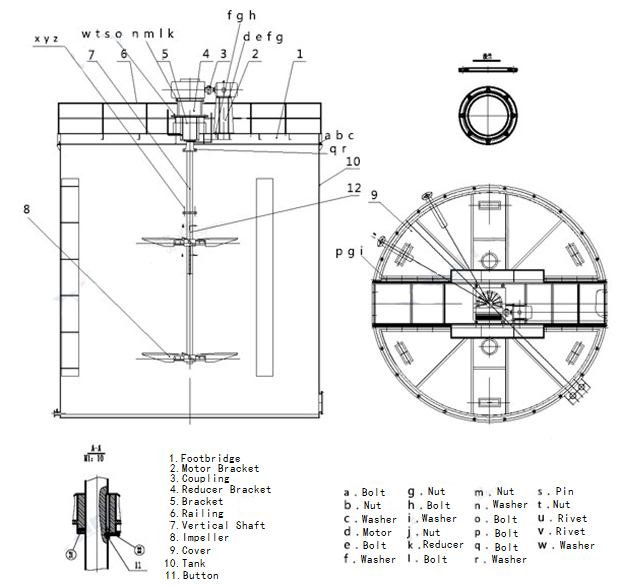

Structure

Under the stirring action of double impellers, the pulp flows from top to bottom in the center, diffuses through the surrounding damper plate, feeds air at the lower end of the shaft, mixes with the pulp and circulates upwards to form a uniform suspension mixture.

Parameter Technical

|

Model |

Tank Diameter * Height mm |

Volume m3 |

Impeller |

Diameter |

Reducer |

Weight kg |

||||

|

Revolution rpm |

Diameter mm |

Feeding Pipe mm |

Discharging Pipe mm |

Model |

Ratio |

Power kw |

||||

|

SJ2.0×2.5 |

2000×2500 |

6 |

52 |

909 |

2—Φ133×8 |

2—Φ133×8 |

XLD2.2-4-29 |

29 |

2.2 |

2144 |

|

SJ2.5×3.15 |

2500×3150 |

13.14 |

935 |

2—Φ133×8 |

2—Φ133×8 |

3095 |

||||

|

SJ3.0×3.0 |

3000×3000 |

18 |

40.85 |

1130 |

2—Φ150 |

2—Φ150 |

XLD4-5-35 |

35 |

4 |

4161 |

|

SJ3×3.15 |

3000×3150 |

18.93 |

43 |

1130 |

2—Φ150 |

2—Φ150 |

4323 |

|||

|

SJ3.15×3.55 |

3150×3550 |

24 |

43 |

1260 |

2—Φ150 |

2—Φ150 |

4583 |

|||

|

SJ3.5×3.5 |

3500×3500 |

30 |

52 |

1310 |

2—Φ150 |

2—Φ150 |

XLD5.5-5-29 |

29 |

5.5 |

5025 |

|

SJ3.5×4.0 |

3500×4000 |

32.7 |

41 |

1310 |

2—Φ150 |

2—Φ150 |

5429 |

|||

|

SJ3.55×4.0 |

3550×4000 |

33.6 |

43 |

1310 |

2—Φ150 |

2—Φ150 |

XLD4-5-35 |

35 |

4 |

5825 |

|

SJ3.7×4.2 |

3700×4200 |

38.4 |

42 |

1310 |

2—Φ150 |

2—Φ150 |

XLD4-5-35 |

43 |

4 |

6153 |

|

SJ4.0×4.0 |

4000×4000 |

38 |

35 |

1750 |

2—Φ159×8 |

2—Φ159×8 |

XLD7.5-7-43 |

43 |

7.5 |

7450 |

|

SJ4.0×4.5 |

4000×4500 |

48 |

35 |

1750 |

2—Φ159×8 |

2—Φ159×8 |

XLD7.5-7-43 |

43 |

7.5 |

7569 |

|

SJ4.5×5.0 |

4500×5000 |

71.57 |

1750 |

2—Φ159×8 |

2—Φ159×8 |

XLD7.5-7-43 |

43 |

7.5 |

10864 |

|

|

SJ5.0×5.6 |

5000×5600 |

98 |

31 |

2046 |

2—Φ159×8 |

2—Φ159×8 |

XLD11-8-47 |

47 |

11 |

14291 |

|

SJ5.5×6.0 |

5500×6000 |

112 |

2100 |

2—Φ159×8 |

2—Φ159×8 |

47 |

11 |

18745 |

||

|

Φ6×6.5 |

6000×6500 |

170 |

24.9 |

2300 |

2—Φ168×8 |

2—Φ168×8 |

XLD18.5-9-35 |

31.5 |

18.5 |

21006 |

|

Φ6.5×7 |

6500×7000 |

215 |

23 |

2400 |

2—Φ168×8 |

2—Φ168×8 |

XLD18.5-9-43 |

43 |

22 |

25567 |

|

Φ7.0×7.5 |

7000×7500 |

245.4 |

21 |

2400 |

2—Φ168×8 |

2—Φ168×8 |

XLD22-10-47 |

47 |

22 |

30486 |

|

SJ7.5×8.0 |

7500×8000 |

268.6 |

21 |

2900 |

2—Φ168×8 |

2—Φ168×8 |

XLD22-10-47 |

47 |

22 |

34365 |

|

SJ8.0×8.5 |

8000×8500 |

342 |

16.4 |

3200 |

2—Φ219×8 |

2—Φ219×8 |

Y250M-8 |

|

30 |

42468 |

|

Φ8.5×9 |

8500×9000 |

395 |

18.5 |

3300 |

2—Φ219×8 |

2—Φ219×8 |

Y250M-8 |

|

30 |

46623 |

|

Φ9.5×10 |

9500×10000 |

648 |

16.6 |

3750 |

2—Φ273×8 |

2—Φ273×8 |

Y280S-8 |

|

37 |

59786 |

|

Φ10.5×11 |

10500×11000 |

900 |

13.28 |

4400 |

2—Φ325×8 |

2—Φ325×8 |

Y315S-8 |

|

55 |

72647 |

|

Φ11.5×12 |

11500×12000 |

1190 |

12.1 |

4600 |

2—Φ325×8 |

2—Φ325×8 |

Y315M-8 |

|

75 |

95669 |

|

Φ12×13 |

12000×13000 |

1414 |

13.4 |

4600 |

2—Φ377×8 |

2—Φ377×8 |

Y315L1-8 |

|

90 |

120635 |

|

Φ13×14 |

13000×14000 |

1740 |

10.7 |

5200 |

2—Φ377×8 |

2—Φ377×8 |

JR125-8 |

|

110 |

148666 |