[Introduction] The motor vibration feeder can feed the bulk and granular materials evenly and continuously from the storage bin to the recieving device. In the sand production line, it can feed the crusher continuously and evenly, and screen the materials roughly.

[Capability] 96-560 t/h

[Application] It is used for continuous and uniform feeding to conveyor, bucket elevator, crusher and ball mill. It is used in automatic control system to realize automation of production process. It is widely used in metallurgy, coal mine, beneficiation, building materials, chemical industry, abrasive industry and so on.

[Improvement] 1. Blind plate and strip screen are used in the bottom plate of feeding trough, which can pre-screen small pieces of material in feeding. 2. Double eccentric shaft vibrator adopted in this feeder.

Chat With Us

Chat With Us

Leave Message

Leave Message

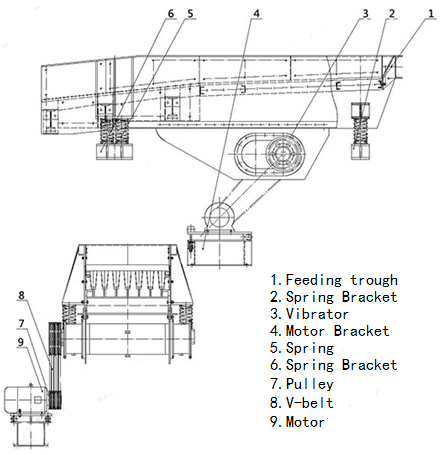

The feeder is mainly composed of vibration frame, spring, vibrator, motor vibration frame and motor. The exciter is composed of eccentric shaft and gear in a specific position. When assembling, the two gears must be meshed according to the mark, and driven by motor to rotate the two eccentric axes, thus generating a huge composite linear exciting force, which makes the body vibrate forcibly on the supporting spring. The material is driven by this vibration to slides and throws on the trough, so that the material moves forward. To achieve the purpose of feeding. When the material passes through the sieve bar on the trough body, the smaller material can fall through the clearance of the sieve bar, and the sieving effect can be achieved without going through the next crushing process.

|

Model |

Trough Size |

Max Feeding Size |

Capacity |

Eccentric Shaft Revolution |

Motor Power |

Weight |

|

mm |

mm |

tph |

rpm |

kw |

kg |

|

|

ZSW-380×95 |

3800×950 |

500 |

96-160 |

800 |

11 |

4082 |

|

ZSW-420×110 |

4200×1100 |

580 |

120-240 |

800 |

15 |

4149 |

|

ZSW-490×960 |

4900×960 |

500 |

120-240 |

800 |

15 |

5351 |

|

ZSW-490×110 |

4900×1100 |

630 |

120-280 |

800 |

15 |

5352 |

|

ZSW-590×110 |

5900×1100 |

630 |

350-500 |

800 |

22 |

6130 |

|

ZSW-600×130 |

6000×1300 |

750 |

400-560 |

800 |

22 |

7800 |