Chat With Us

Chat With Us

Leave Message

Leave Message

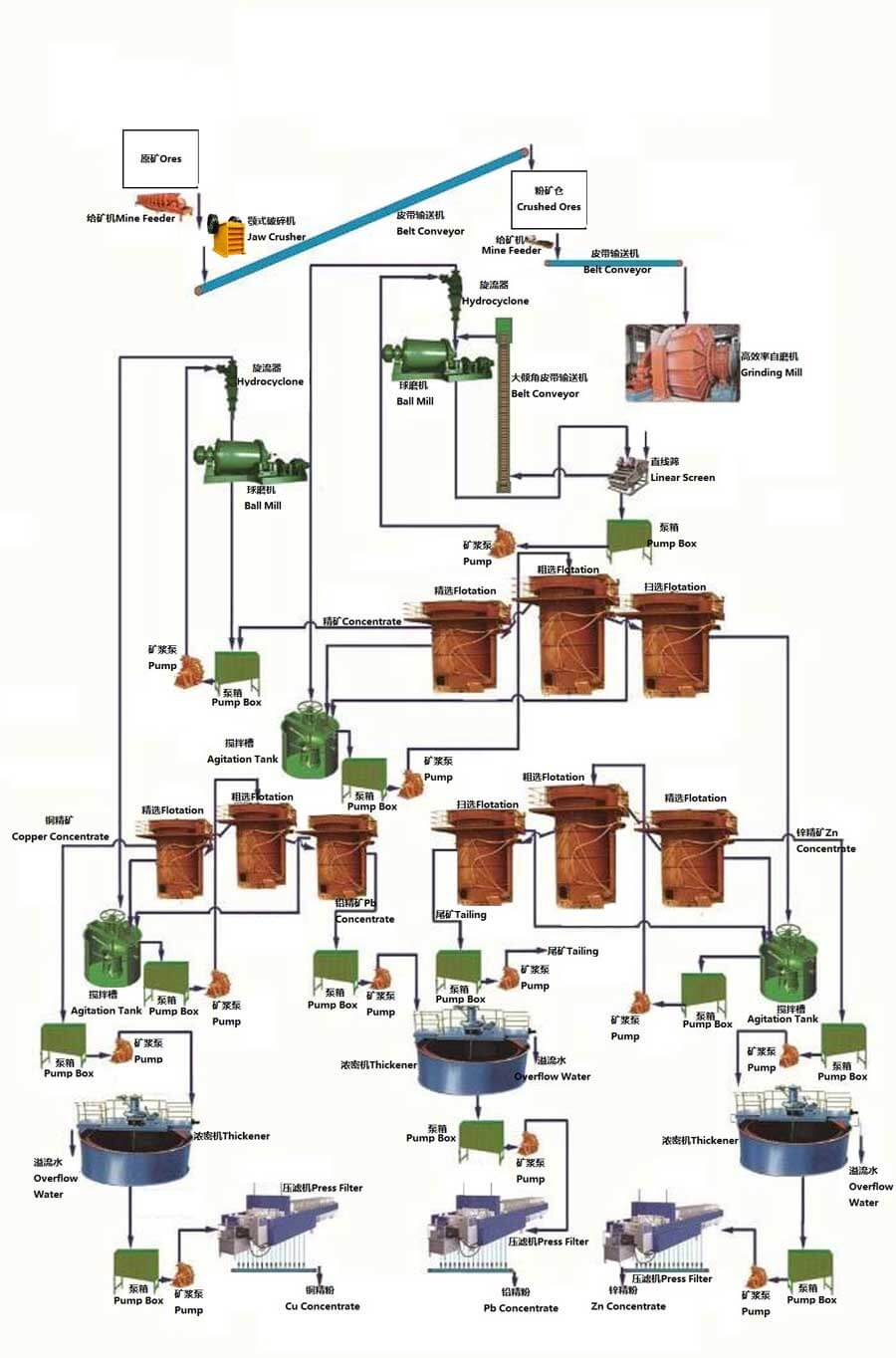

Lead and zinc in nature are generally symbiotic, not easy to dissociate and the metal particle are uneven distributed, the ores can be divided into sulfide ore and oxidized ore, for most cases, copper is symbiotic with lead-zinc.

The regrinding process of copper-lead mixed concentrate does not need to grind all the raw ore finely, so as to save the cost of grinding. At the same time, the regrinding of concentrate can further separate the monomer of copper-lead concentrate, and play a good de-pesticide effect, creating favorable conditions for the separation of copper and lead. In the rough separation, we must strictly carry out chemical usage system to control the dosage of chemicals, to recover metal as early as possible, which can reduce the loss of multiple cycles and inaction, make full use of the two enrichment of foam, and wash the concentrate foam by proper addition of water to reduce the impurities in the foam, so as to enhance the purpose of flotation. The flotation process of lead-zinc sulfide ore can be divided into direct priority flotation process, mixing-separation flotation process and asynchronous flotation process.