Chat With Us

Chat With Us

Leave Message

Leave Message

Potassium feldspar is mainly composed of orthoclase, microcline and striped feldspar, i.e. aluminosilicate minerals of alkali metals such as potassium, sodium and calcium or alkaline earth metals.

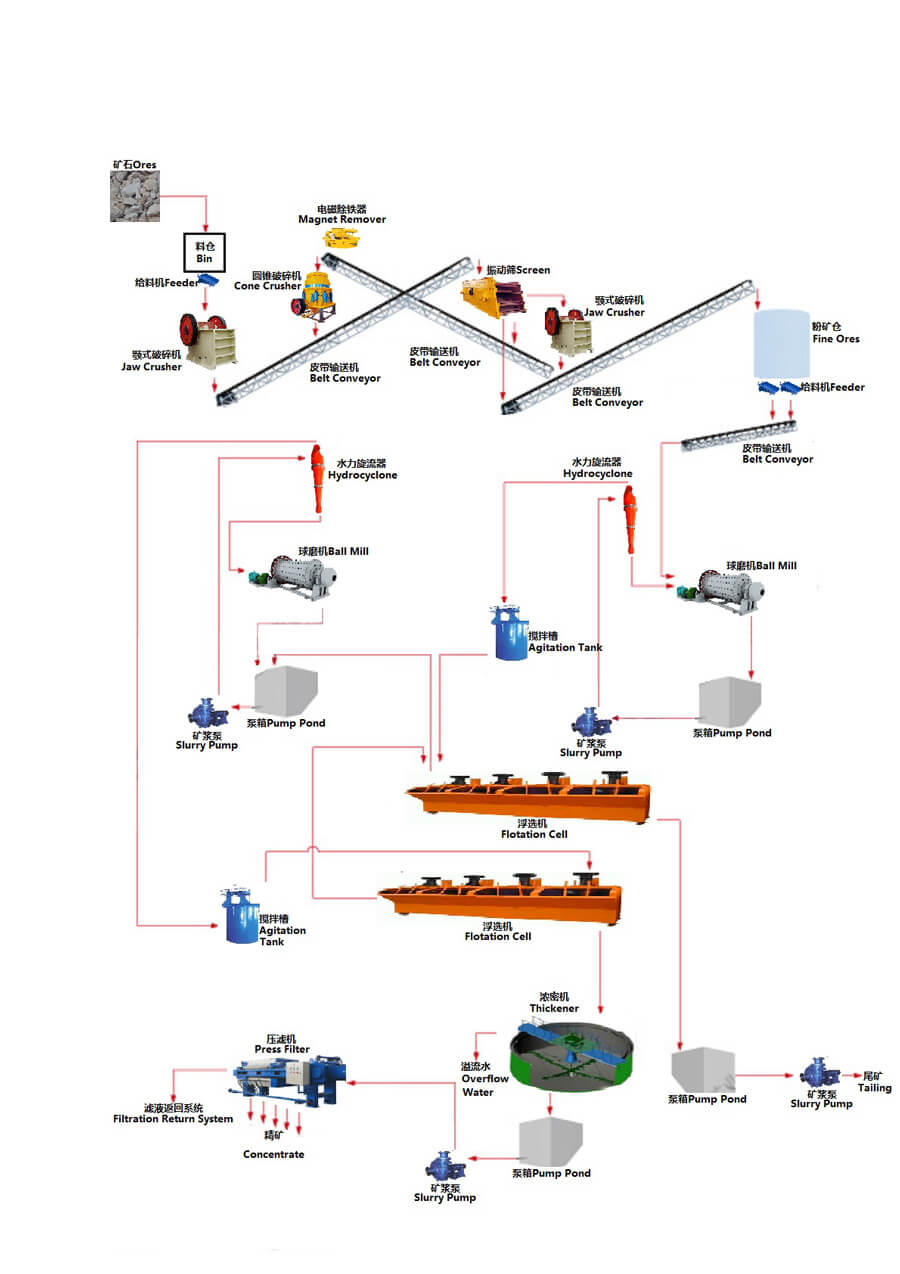

1.Crushing

Crushthe ores into small rocks.

2.Grinding

Grind the crushed ores via grinding mill to be 0.074~0.5mm.

3.Mud Washing

Separate the fine ores of 0.074~0.5mm by spiral chute.

4.Sorting

After spiral chute, separate the ores by shaking table to remove the iron oxide.

5.Fine Separation

After shaking table separation, send the concentrate to the high-intensity magnetic separator to remove iron and mica, and then feed the concentrate into next magnetic separator for further sorting.

6.Purification

Use high frequency vibrating screen to further separate ore powder, remove iron trioxide and iron tetroxide from the powder, and obtain fine potassium feldspar powder.

7.Pickling powder

Using sulfuric acid as pickling agent, according to the concentration of acid and the iron content of potassium feldspar powder, the iron content of potassium feldspar powder is proportional to the sulfuric acid content. After pickling, the ferrous oxide and ferric tetroxide are removed completely, and the ferrous sulfate solution is separated to obtain potassium feldspar powder.

8.Screening of potassium feldspar concentrate powder

The feldspar concentrate powder is fed into 20-200 meshes for screening, and the product with iron content less than 0.24%.