Chat With Us

Chat With Us

Leave Message

Leave Message

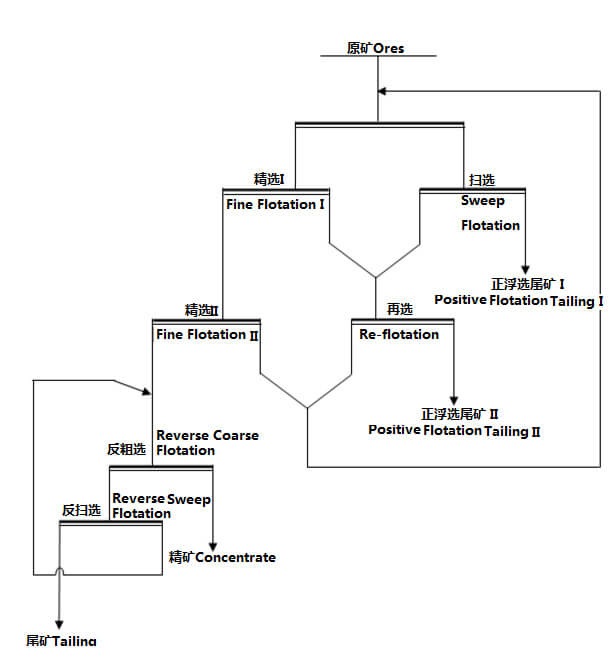

Phosphate flotation equipment production line can be applied to phosphate ores with complex ore structure, complex mineral occurrence relationship, fine grain size, close mosaic relationship, common mixed symbiosis and difficult monomer dissociation.

Direct flotation is to use effective inhibitors to suppress gangue minerals, and to collect phosphorus minerals in foam by collectors, which can be applied to low grade phosphate rock, including magmatic rock apatite and sedimentary metamorphic phosphorite minerals.

It is mainly used for the separation of phosphate rock and dolomite. Dolomite is floated in weak alkaline medium with aliphatic acid collector. Phosphorus minerals are concentrated in the tank. Its advantage is to realize flotation at room temperature. Coarse particle size of the product in the tank is beneficial to the post-treatment of the product.

Double reverse flotation is to separate target minerals by anionic collector with positive charge on silicate surface under alkaline conditions. That is, dolomite is first flotated, then silicate is reverse flotation. The product in the tank is heavy concentrate. The production line can be carried out at room temperature and with coarse grain size.