Chat With Us

Chat With Us

Leave Message

Leave Message

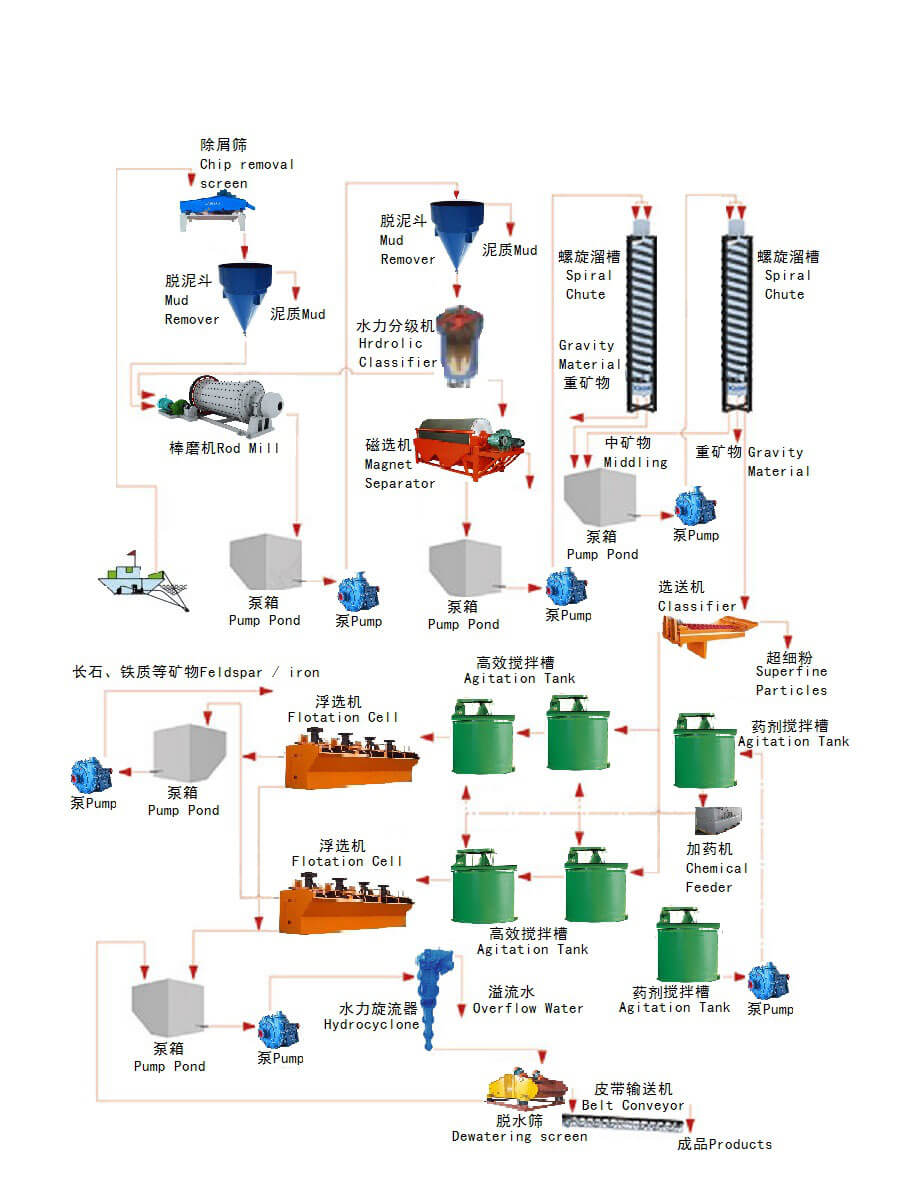

Purification of quartz sand is a complicated separation technology to remove impurities in quartz sand and obtain refined quartz sand or high purity quartz sand. The main purification processes of quartz sand are water washing, grading desliming, scrubbing, magnetic separation, flotation, acid leaching, microbial leaching, etc.

The grade of silica (SiO 2) in quartz sand are affected by the grain size of quartz sand, especially in quartz sand containing a large amount of clay minerals. It is necessary to wash and desliming quartz sand before separation process.

Scrubbing is to remove the thin film iron and muddy impurity minerals on the surface of quartz sand by means of mechanical force and abrasion force between sand grains, and further crush the mineral aggregates that have not become monomers, and then achieve the effect of further purification of quartz sand by grading operation. At present, the main methods of scrubbing are rod scrubbing and mechanical scrubbing.

The separation of mica and quartz is difficult. Good results can be obtained by using anionic collector in acidic condition or anionic-cationic collector in alkaline condition. Generally, after scrubbing, desliming, magnetic separation and flotation, the purity of quartz sand can reach more than 99%, basically meeting the needs of industrial sand.

Dilute acid has remarkable effect on the removal of iron and aluminium, while the removal of titanium and chromium is treated by acid leaching with concentrated sulphuric acid and aqua regia. Usually, the mixed acid composed of the above acids is used for the removal of impurity minerals. The control of various factors in acid leaching should be based on the requirement of final quartz grade and try to reduce the concentration, temperature and dosage of acid in order to purify quartz at a lower cost of beneficiation equipment.

The separation of iron impurities in quartz by high magnetic separator is a key point. For high quality quartz sand, strong magnetic separator must be used to remove magnetic impurities.